The area of Microsensors & Microfluidics concentrates on the miniaturization of sensor and fluidic systems based on silicon, glass or polymers, and offers the corresponding technologies.

One of our activities involves the development of highly miniaturized active medical implants, some of which can be placed in the oral cavity, such as the salivary stimulator Saliwell with closed loop control as well as the drug delivery system IntelliDrug.

In the field of microfluidics we focus on realizing microfluidic systems to handle biological cells, e. g. cell transportation or cell separation.

The area also concentrates on the integration of biochips in Lab-on-Chip. We are well grounded in a long-standing know-how as well as numerous technologies for biochip-compatible assembly and interconnection technologies and the realization of microfluidic systems. Above all, the cross-institutional cooperation within the Fraunhofer Society allows the customized development of complete analytical systems.

Microsensors & Microfluidics

Microfluidics for Cell Handling

Microfluidic channel systems combined with electrodes can either be made of polymeric materials or using classical MEMS materials such as silicon and glass. Biocompatible dry film resists as well as SU-8 photoresist can be applied for prototyping and for small batches. Real mass production is possible by exploiting a new roll-to-roll hot embossing process in combination with capping of embossed micro channels by a rotary lamination process. Materials like COC, PC, PMMA, PS etc. are available.

Examples:

- micro injection chip

- cell sorting chip

- micro and nano patterned surfaces for studying cell behaviour

Micro Sensor and Actuator Development

Silicon-based MEMS technology in combination with additional micro system technology allows the fabrication of miniaturized sensors and actuators. There is an emphasis on sensors and actuators for medical devices, especially medical implants. In the past a focus was on miniaturized systems for application inside the oral cavity.

On demand: all sensors and actuators can be provided with a telemetric link for wireless control or data transfer.

Examples:

- micro flow sensor for a drug delivery system

- wetness sensor for the oral cavity

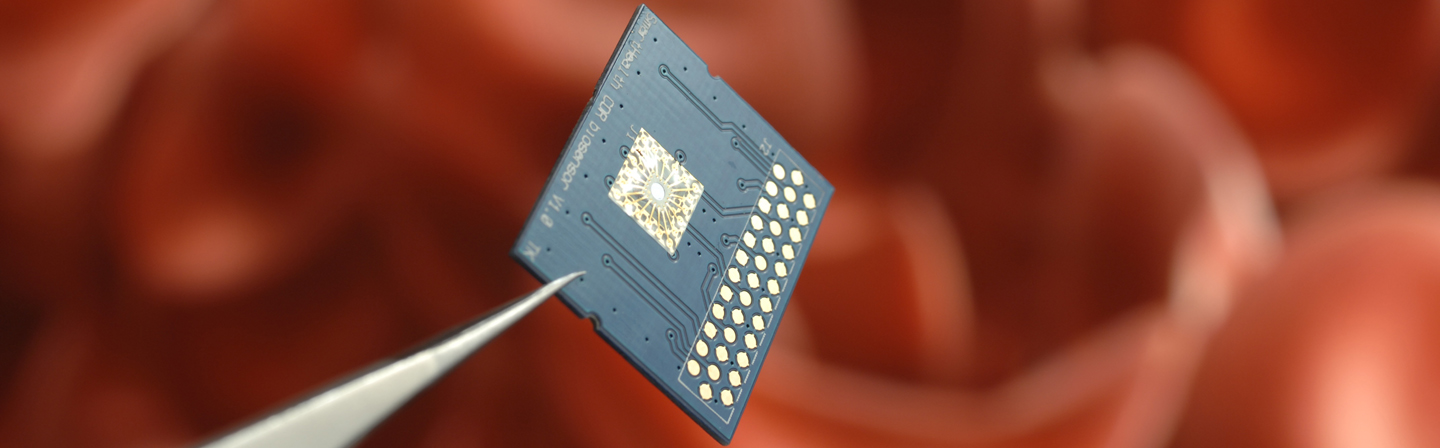

Packaging of Biochips

Microfluidics and biochip-compatible packaging are the typical enabling technologies which can convert a bare biochip into a device with practical utility in the macroworld. Microfluidic technology provides the interface for the fluid supply of miniaturized biosensor elements. Several concepts and technologies for supplying the fluids to the biosensor element as well as for the fluidic interface to the user are available. They take into account that sample injection should only contaminate the cheap and disposable parts of the system. Concepts and technologies for the electrical interface are also available. The applied micro-assembly and encapsulation techniques allow a strict separation between fluid channels and sensitive electronic structures both on the biochip and the entire lab-on-a-chip.

Examples:

- Packaging of a multianalyte biochip based on an array of nine monolithic optoelectronic transducers

- Packaging of a silicon-based resonating-type biochip