One focus of the research and development activities in the area of Biomedical Microsystems is in the field of active implants. Our range of services related to active implants is based on more than 20 years of experience in various fields of application. In our current projects we focus on the further miniaturization of implanted systems in connection with wireless power supply and communication. This often requires specific communication concepts in order to meet the specifications required by the customer, the regulatory requirements and also the general conditions dictated by physics. Recently, we set a milestone in the field of energy and data transmission to implants: A cooperation with the ultrasound department of the Fraunhofer IBMT has resulted in an ultrasound-based energy and data transmission system for active implants, which has advantages over electromagnetic transmission systems for certain applications. The hardware used for wireless signal and data transmission is currently being further miniaturized. For this purpose, we develop capacitive ultrasonic transducers, so-called cMUTs, which are specially optimized for communication with implants and manufactured using microsystems technology.

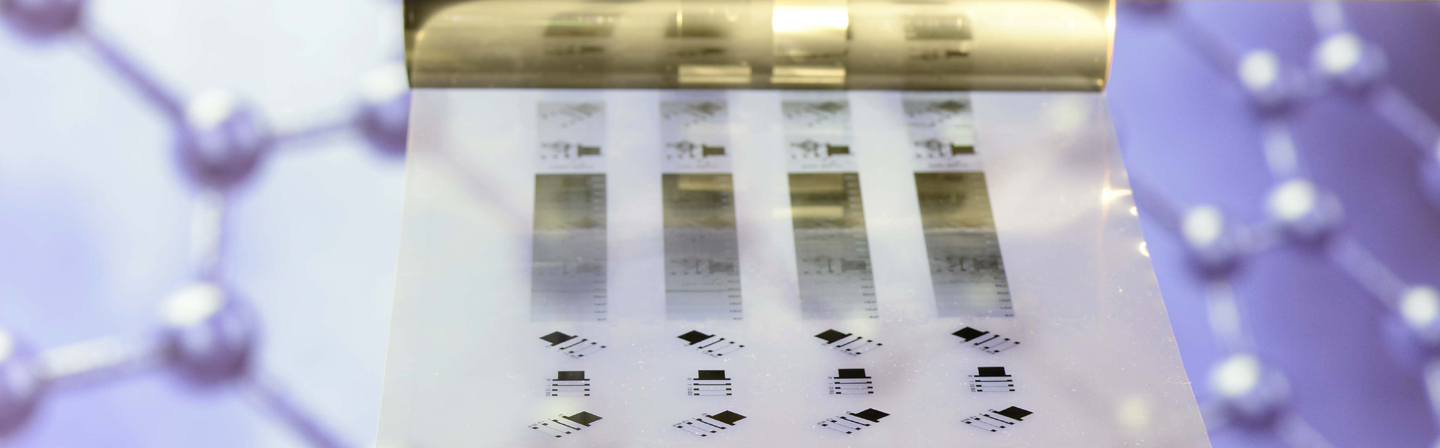

Another focus of our work is the development of cell-based biosensors and organ-on-chip systems, which is done in close collaboration with the department of Bioprocessing and Bioanalytics. Here, the department has many years of know-how in the fields of miniaturization, production and integration of sensory and microfluidic systems based on materials such as silicon, glass or plastic. Alongside the conventional methods of microsystem technology, we are increasingly using roll-to-roll processes that are suitable for mass production at low manufacturing costs. This includes the roll-to-roll hot embossing of microfluidic structures, the printing of electrically conductive structures such as for example graphene structures, as well as the printing of protein structures on the micrometre scale with a self-developed protein ink. Rotogravure printing, screen printing and inkjet printing are available. Current research projects aim at printing entire biosensors.

By combining miniaturized electronics with sensors or electrodes, we realize monitoring systems with close skin contact that are comfortable to wear. We use such wearables to improve human-technology interaction. The recorded data, such as vital parameters or acceleration signals, are evaluated using machine learning methods at the point of acquisition. We use special tools to train learning algorithms and port them to the microcontroller of the wearable. In current research projects, we are developing context-sensitive therapy glasses that vary the therapy depending on the type of physical activity detected. In another example, we continuously adjust the intensity of anxiety therapy to the patient's anxiety sensation in order to achieve optimal efficiency of the exposure therapy.