Application-specific product developments generally finalize in the manufacturing of demonstration models or prototypes. The transition to market introduction requires a refinement of these achieved results.

This is exactly where the working group of Manufacturing Technology comes in to offer the customer support on the way to market introduction of a product. This can apply to either newly developed or existing sensors.

In order to cover the widest possible bandwidth in this area, we offer the following services:

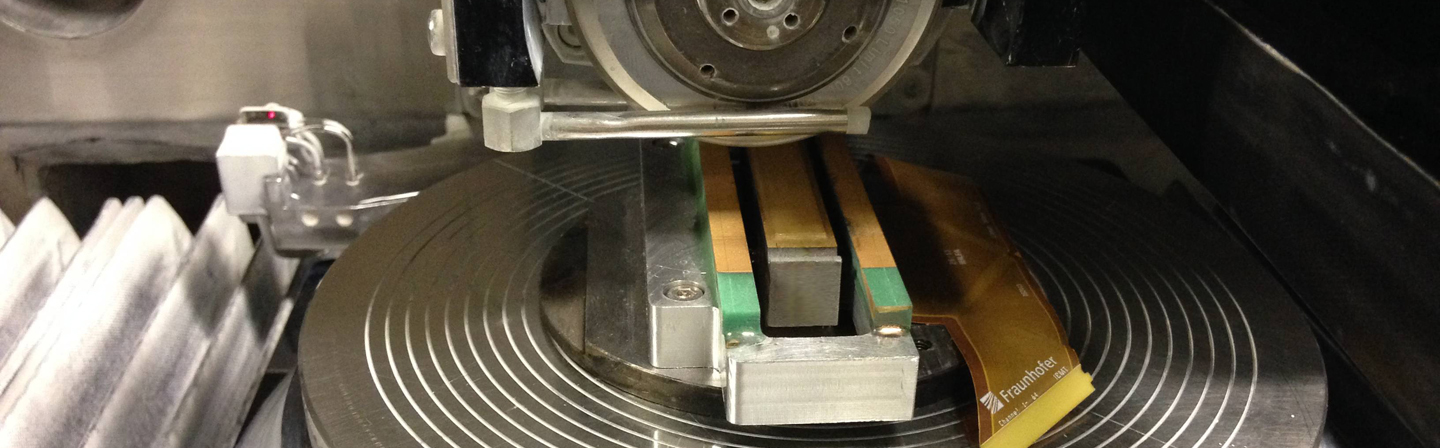

- development and optimization of production processes

- development and realization of production equipment

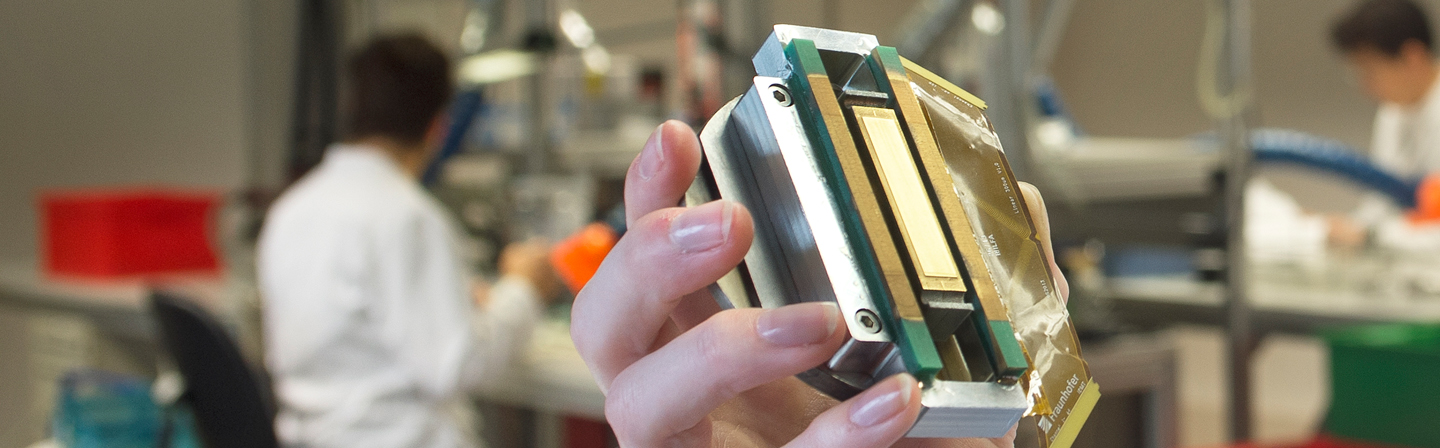

- manufacturing of prototypes and pilot series in accordance with ISO 9001

- quality assurance

- advice and support in sensor production technology.

These services can be applied to a wide range of sensors from industry, medicine or sonar. Possible examples include:

- ultrasound transducers for fluids (e. g. flow measurement, level measurement)

- ultrasound transducers (e. g., distance measurement, material analysis, wind measurement)

- ultrasound transducers for sonar applications

- 1-3 piezocomposites up to 10 MHz

Particular mention should be the competence in the production of piezocomposites. Special production processes coordinated in terms of equipment and parameters serve as the foundation and can be adapted and optimized for customer-specific applications.

The close structural connection with product development offers direct communication paths and thus represents a special advantage of the working group of manufacturing technology.